Cov Khoom Siv Laminate Rigid & Machined Part

Cov Laminate Rigid

● Cov Ntawv Feem Ntau Rau Cov Ntawv Siv Hluav Taws Xob

| Qib | Thermal | Cov yam ntxwv tseem ceeb |

| 3025 | E-105 ℃ | Hnav-resistant |

| 3240 | B-130 ℃ |

|

| 3253 | H-180 ℃ | Lub zog kho tshuab siab heev nyob rau hauv qhov kub siab, tsis muaj halogen |

| D326 | H-180 ℃ | Lub zog kho tshuab siab heev nyob rau hauv qhov kub siab |

| D333 | C-200 ℃ | Lub zog kho tshuab siab heev nyob rau hauv qhov kub siab |

| 3242 | F-155 ℃ |

|

| D327 | F-155 ℃ | Kev khaws cia kub zoo, V-1 |

| D328 | F-155 ℃ | Kev khaws cia lub zog kub siab, V-0, UL, benzoxazine resin |

| DF204 | F-155 ℃ | Kev khaws cia lub zog kub siab, V-0, UL, epoxy resin |

| D331 | H-180 ℃ | Kev khaws cia lub zog kub siab, V-0, UL, benzoxazine resin |

| D329 | H-180 ℃ | PTI ≥ 500V, V-0, tsis muaj halogen |

| D338 | H-180 ℃ | V-0 |

| D330 | B-130 ℃ | Semi-conductive, dub |

| D339 | F-155 ℃ | Semi-conductive, dub |

| D350A | H-180 ℃ | Kev khaws cia lub zog kub siab |

| EPGC201 / 202 | B-130 ℃ | G10 / FR4 (UL) |

| EPGC203 / 204 | F-155 ℃ | G11 / FR5 (UL) |

| EPGC205 | F-155 ℃ | Iav roving tiaj tus weaving ntaub |

| EPGC306 | F-155 ℃ | CTI ≥ 500V |

| EPGC307 | F-155 ℃ | CTI ≥ 500V, Iav roving tiaj tus weaving ntaub |

| EPGC308 | H-180 ℃ | Kev tiv thaiv siab tom qab kev nqus dej |

| DF3316A | C-200 ℃ | Kev kub siab tsis kam |

| DF336 | F-155 ℃ | CTI ≥ 600V, V-0, tsis muaj halogen |

● Cov Ntawv Rau Cov Ntawv Thov Uas Tsis Yog Hluav Taws Xob

| Qib | Thermal | Cov yam ntxwv tseem ceeb |

| D332 | F-155 ℃ | Hnav-resistant |

| D3524A | F-155 ℃ | Dub, hluav taws kub retardant, siab zog |

| DF3524B | F-155 ℃ | Qhov ceev qis, hluav taws kub retardant, siv ua cov khoom siv tseem ceeb |

| D325 | — | Kevlar tiv thaiv kev tawm tsam, kev tiv thaiv kev ruaj ntseg |

| D295 | — | Prepreg. ntawm Kevlar ntaub rau ballistic helmets, Kev tiv thaiv kev ruaj ntseg |

| D332 | F-155 ℃ | Hnav-resistant |

| G3849 | H-180 ℃ | Siv rau hauv cov khoom siv cryogenic (kub qis rau -196 ℃) |

| D3849 | F-155 ℃ | Siv rau hauv cov khoom siv cryogenic (kub qis rau -196 ℃) |

| Z3849 | B-130 ℃ | Siv rau hauv cov khoom siv cryogenic (kub qis rau -196 ℃) |

| DF3313L | B-130 ℃ | qhov ceev tsawg, lub teeb hnyav, Cov ntawv rwb thaiv tsev zoo |

| DF3314O | F-155 ℃ | qhov ceev tsawg, lub teeb hnyav, Cov ntawv rwb thaiv tsev zoo |

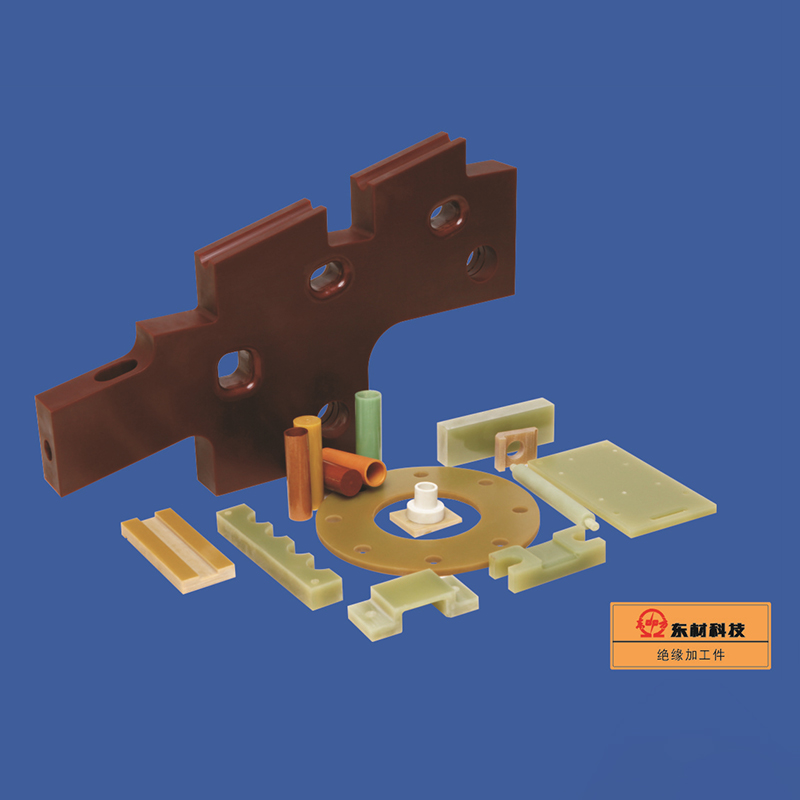

Tshuab Ib Feem

Cov khoom siv tshuab feem ntau yog ua los ntawm SMC, BMC, UPGM203 (GPO-3) prepreg, EPGC202 (FR4) thiab lwm yam khoom siv raw los ntawm kev nias kub lossis epoxy resin / epoxy vinyl resin / unsaturated polyester resin pultrusion forming.

● 工 - Hom

● U - Hom

● L - Hom

● 王 - Hom

● Z - Hom

Cov ntawv thov

Cov khoom siv rwb thaiv tsev uas muaj cov fiber ntau ntxiv uas ntev tshwj xeeb

Siv tau rau kev tsim hluav taws xob thermal (kev tsim hluav taws xob pov tseg hauv nroog, kev tsim hluav taws xob roj pov tseg)

● Qhov Rooj Liner

| Kev ua tau zoo | Chav tsev | Cov nqi | |

| 1 | Lub zog khoov (ib txwm) | MPa | ≥210 |

| 2 | Lub zog khoov ntsug (160 ℃ ± 2 ℃) | MPa | ≥170 |

| 3 | Lub zog nias | MPa | ≥320 |

| 4 | Lub zog tensile | MPa | ≥270 |

| 5 | AC Voltage tsis kam | V/60s | 6000 |

● Cov ntaub thaiv cua sov

| Kev ua tau zoo | Chav tsev | Cov nqi | |

| 1 | Lub zog khoov | MPa | ≥400 |

| 2 | Lub zog tensile (ntsug) | MPa | ≥300 |

| 3 | Lub zog hluav taws xob ntsug laminar (90 ℃ roj) | MV/m | ≥16.1 |

| 4 | CTI | V | ≥500 |

● Lub nplhaib rwb thaiv tsev

| Kev ua tau zoo | chav tsev | Cov nqi | |

| 1 | Lub zog khoov | MPa | ≥400 |

| 2 | Lub zog compression ntsug laminar | MPa | ≥300 |

| 3 | Kev poob siab thermal 320 ℃ / 1 teev | __ | Tsis muaj de-lamination, npuas, resin ntws |

| 4 | CTI |

| ≥50 |